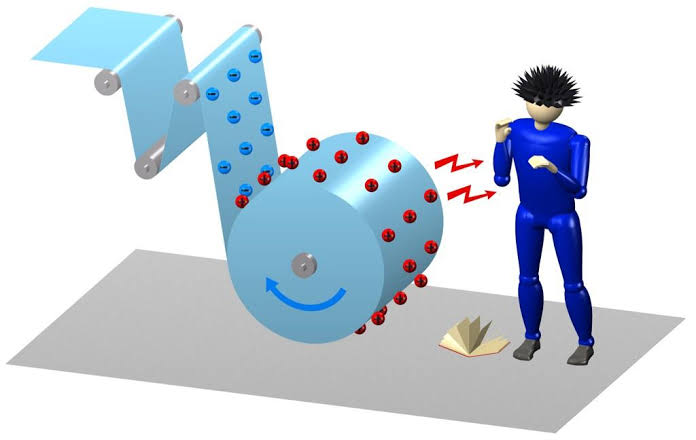

A very common problem is when people get static shocks from working close to objects that carry a high electrostatic charge.

Problems occur when machine operators come close to highly charged materials eg.

film on a roll at a winding or unwinding section.

A direct spark can jump from the object to the person which is unpleasant and sometimes dangerous.

The person can also become charged by standing close to the charged object. A spark will occur only when the person comes near to a grounded metal surface.

How can you stop static shocks? In both cases the solution is not related to the person. The solution is to prevent a high static charge building up on the object. Static charges should be reduced by fitting anti-static devices at the last stage off the process, where the person gets a shock or becomes charged. In most cases this will solve the problem. Occasionally the charge generation is so high that the object needs to be discharged at other points throughout the production process. The anti-static equipment in the last stage will then reduce the remaining charge to a safe level.